Remanufacturing

Raeuse is the better way to recycle: good for you, better for the planet.

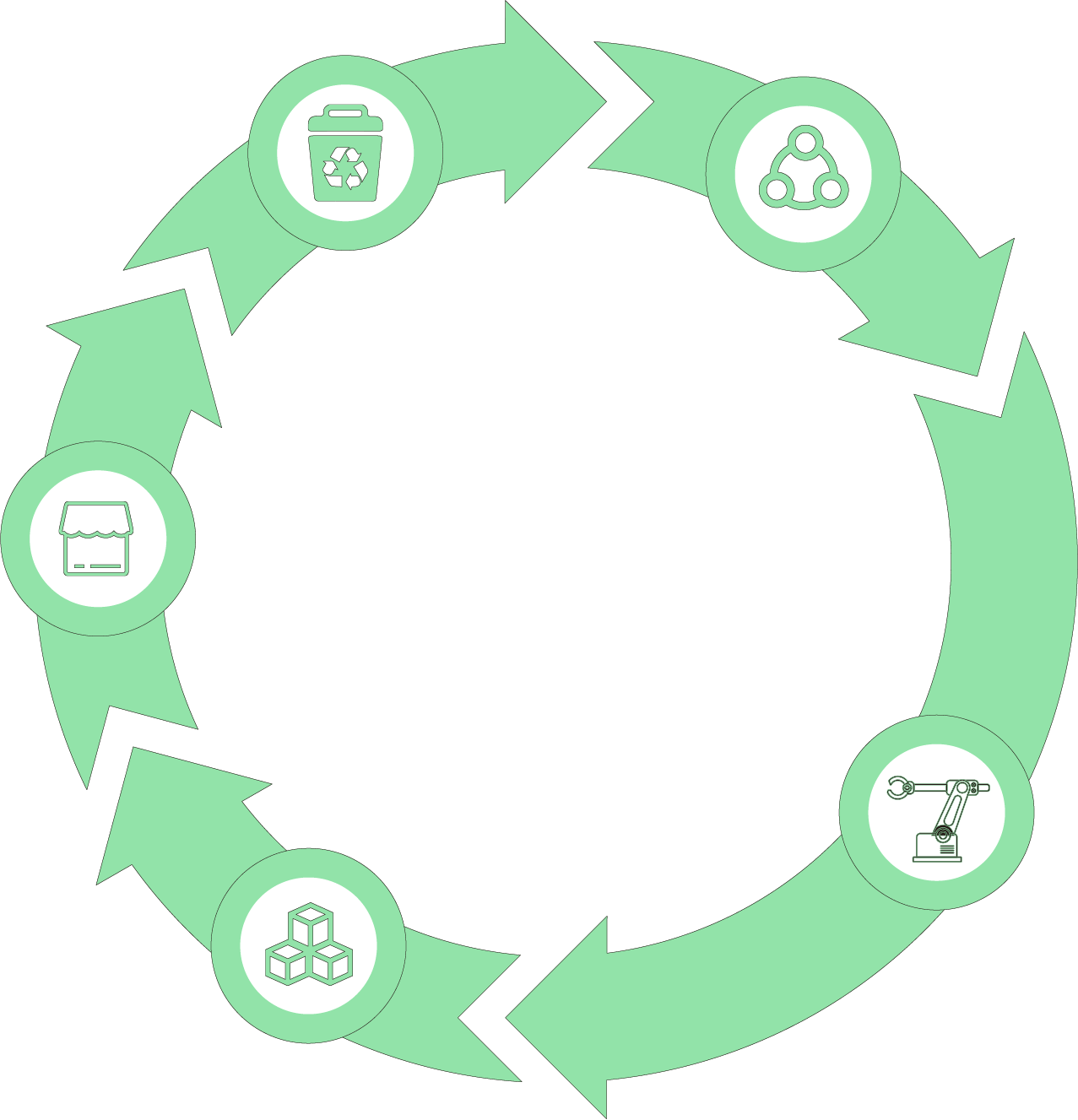

OUR CLOSED LOOP REMANUFACTURING

Remanufacturing Contributes to a Sustainable Future

Ever since it was established

in 2000, Ninestar has been providing a closed loop solution with

remanufactured printer cartridges. Consumers can return their used

cartridges at no cost, the cartridges are sorted, cleaned,

remanufactured, packaged and stored ready for reuse. The whole process

at Ninestar is continually being scrutinised to minimize our carbon

footprint and to help save the planet.

03 Ninestar Remanufacturing Production

Solar powered,

automated production lines and water treatment plants are part of the

strategy to deliver the most environmentally friendly printer cartridge

solution in the world.

04 Ninestar Warehouse

Every

remanufactured cartridge is tagged so that it will be stored ready to be

returned for reuse in the country where it originated.

05 Shopping Sites

Customers can be confident in the

consistently reliable and high-quality remanufactured ink and toner

cartridges meet a wide range of the most stringent environmental

certifications and standards set by governments and peak industry

bodies.

01 Used Cartridge Collection

End-users return their empty cartridges using a post-free envelope or drop them off at their nearest recycling site.

Ninestar co-operates with empty collection partners in many regions.

02 Recycling

Cartridges are sorted and graded at the

Ninestar recycling center. The premium quality empties are separated and

made ready for remanufacturing. Other plastic and metal wastes are sent

to accredited recycling centres.

Ninestar Closed Loop Recycling System

Helps minimize our environmental footprint and save the planet.

Respect the structure and integrity of the

original used cartridge and maximise its future usefulness through the

entire remanufacturing process.

Reuse as much of the empty, used cartridge as possible and ensure the

worn-out components and parts are recycled and do not end up in

landfill.

Implement environmentally safe production practices throughout the remanufacturing process.

Industry-leading Processes

Ninestar’s remanufactured

cartridges meet stringent quality standards. Each link of the production

chain is constantly monitored by Quality Control experts including the

cleaning, production, packaging, storage and shipping.

Remanufacturing Ink Cartridges

Sorting & Grading

All incoming raw materials undergo rigorous inspection, sorting,

and grading process by skilled technicians before they head off to the

production lines. Only superior empty cartridges are reused. All others

are broken down for their plastics and metals and sent to accredited

recyclers.

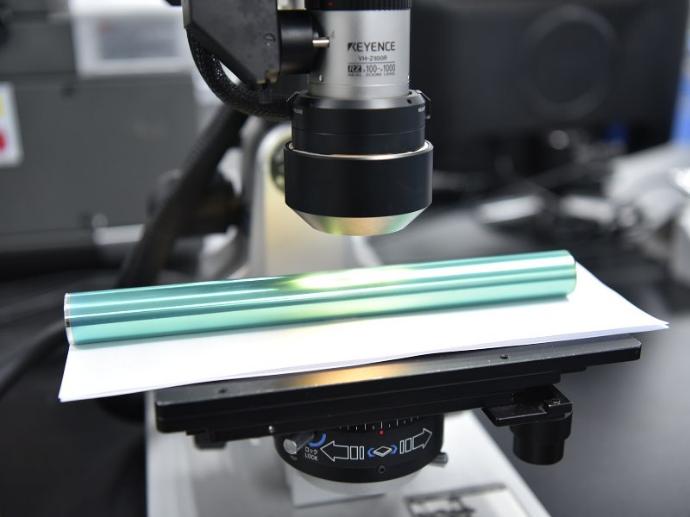

Circuit Inspection

The integrity of every micro circuit is electrically tested on

cartridges to guarantee they are in perfect condition ready for reuse.

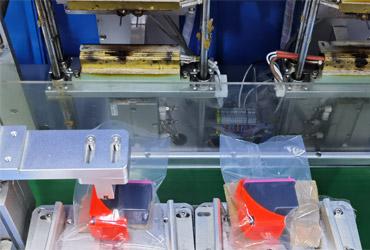

Auto Cleaning

With Ninestar’s advanced automated equipment, each cartridge goes

through a 3-step cleaning process to ensure no waste ink or other

contaminants remain.

Auto Drying

Each empty cartridge is completely dried in Ninestar’s automated

self-dryer process line to prevent any damage to the shell casing.

Auto Ink Filling

Using cutting-edge, automated filling technologies, each cartridge

is filled precisely to the specified amount with high-quality,

OEM-equivalent ink.

Post Testing

Cartridges are post-tested as part of the production line process

to assure dependable performance and outstanding results. Every

cartridge with a printhead is post-tested.

Sealing & Protection

Ninestar seals each cartridge using state-of-the-art technology to

guarantee zero leakage and a smooth user experience. Special protection

is added to those cartridges with printheads.

Packaging & Shipping

Each cartridge is heat-sealed and packed in its own unique box.

Simulated transport tests are run to confirm the integrity of the

cartridge and the packaging before shipment.

Remanufacturing Toner Cartridges

Sort & Grade

All incoming raw materials undergo rigorous inspection, sorting,

and grading process by skilled technicians before they head off to the

production lines. Only superior empty cartridges are reused. All others

are broken down for their plastics and metals and sent to accredited

recyclers.

Split & Clean

All empty cartridges are dismantled by specially designed tools then carefully cleaned to avoid toner contamination.

Matching Test

Extensive matching tests are conducted under different conditions

to make sure all the components work in harmony with each other over the

life of the cartridge.

Parts Performance Tests

All key components including OPCs, wipe blades, doctor blades, magnetic rollers and PCRs are tested for possible replacement.

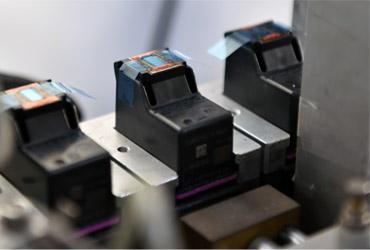

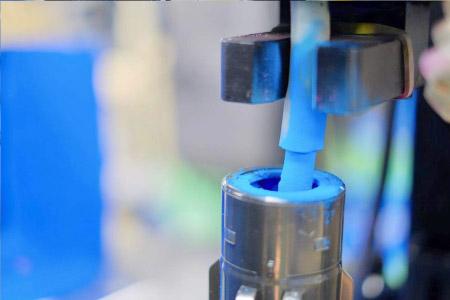

Automated Toner Filling & Vacuuming

Cartridges are automatically filled with premium toner powders,

capped then vacuumed to make sure there is no residual toner on the

casing.

Sealing

A sealing strip is applied to each toner cartridge to ensure zero leakage.

Assembly

The components and parts are assembled by well trained technicians

and cross checks are applied to ensure the quality of each step in the

rebuilding of the cartridge.

Chip Inspection

Microchips are installed carefully to make sure every cartridge will be recognized easily by the printer they will be used in.

100% Post Testing

Every cartridge is post tested as part of the production line procedure.

Appearance Inspection

The appearance of every cartridge is visually checked by trained

staff with keen eyesight for picking up even small discrepancies in each

cartridge.

Sampling Test

2% of every production batch is sample tested with a page run of more than 200 pages each.

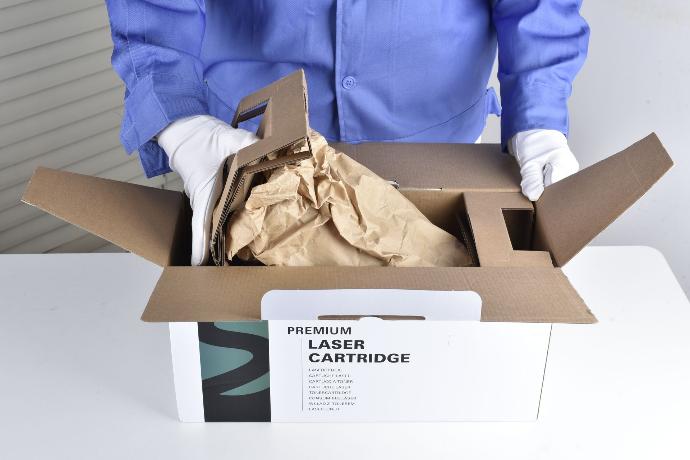

Packaging

Each cartridge is heat-sealed in a light-proof bag to make sure

the sensitive OPC is well protected. The cartridge is carefully placed

in a clean, attractive well-padded box ready for despatch.